Lighting and harness manufacturer Peterson Manufacturing says it will hold or reduce prices on nearly all its product lines in 2026, crediting automation, vertical integration, and tight control over production costs for helping it withstand inflationary pressures.

Al Anderson, vice-president of sales and marketing, said the company has not adjusted its price list since Jan. 1, 2023, and its upcoming “price adjustment,” scheduled for Jan. 1, 2026, will see 96% to 97% of products stay flat or drop.

“It’s all about innovation and manufacturing control,” he told journalists visiting the manufacturer’s Grandview, Mo., facility in the greater Kansas City area. “When you build everything yourself, you can manage costs others can’t. We’ll see some minor shifts — a few up, but most staying the same or going down.”

Executives said the company’s deep vertical integration — from tooling to molding to electronics — allows it to react quickly to changing market conditions and maintain price discipline even as competitors face rising component costs.

6,000 wiring-harness configurations

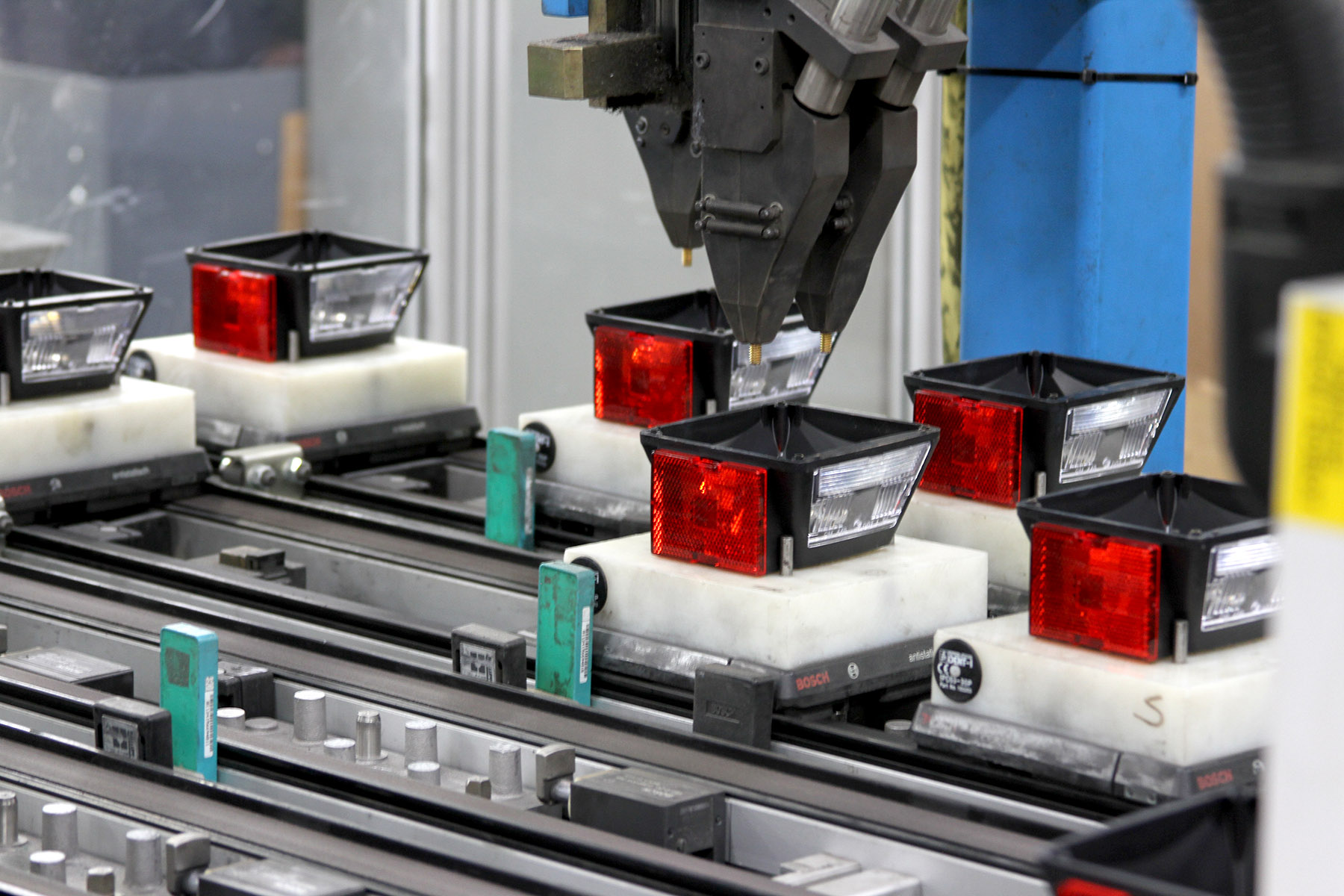

Peterson’s Kansas City headquarters spans 44 acres and 675,000 square feet, housing four factories under one roof. “Volume drives automation,” said executive vice-president of operations Jim Rash. “We’re reducing labor, improving consistency, and keeping our prices stable.”

Founded in 1945 and family-owned since 1956, Peterson has evolved from making tire pumps in downtown Kansas City to producing more than 2,500 lighting part numbers and 6,000 wiring-harness configurations for trucks, trailers, motorcycles, and off-road equipment.

Tooling and plastics work happen entirely in-house. The company’s Vector Tool and Engineering unit machines precision molds used by Mission Plastics, which forms housings and lenses later assembled into finished lighting at Peterson’s main factory. Rash noted that if a mold issue comes up, employees walk it across the hall instead of waiting six weeks for a supplier.

Fighting corrosion and failures

Corrosion remains the most expensive electrical-failure problem in commercial trailers, worsened by the chemicals used to keep highways clear in winter. Peterson’s Defender and Patriot sealed harness systems are designed to exclude moisture and contaminants at the connector, and the company offers what it calls the industry’s only corrosion warranty when fleets buy Peterson lights and harnesses together as a system.

“Lighting problems aren’t really about bulbs anymore,” Anderson explained. “They’re about connectors, seals, and corrosion. That’s where our systems approach makes a difference.”

Smart trailers and actionable data

Peterson’s Pulse solution extends that systems philosophy into telematics and diagnostics. It can pinpoint individual lamp-out conditions, read ABS fault codes, and monitor brake-line air pressure to detect dragging brakes or spring-brake release issues.

“We don’t want to flood fleets with data they can’t use,” Anderson said. “We focus on actionable insights — things that keep equipment moving safely and prevent roadside events.”

The technology signals a broader move by fleets and OEMs to reduce complexity by consolidating their vendor networks. Anderson said customers increasingly prefer to work with a single provider that can take full responsibility for the performance and reliability of their systems.

Internally, Peterson is relying on its own data to steer growth. The company’s sales-forecasting meeting combines macro-economic indicators with feedback from field sales staff. Anderson added that real-time data drives planning.

Peterson’s approach is part of a broader shift toward what executives call “connected confidence” — grounding decisions in field intelligence while maintaining flexibility through automation and in-house production.

Connected trailer technology

When it comes to connected trailer technology, Anderson said adoption remains uneven across market segments. Refrigerated fleets have led the way for years because temperature-sensitive freight can spoil with just a two-degree swing. Tanks are catching up fast because of product integrity and cargo theft concerns. Chassis fleets are very cost-driven, so they’ll be last to move beyond basic GPS, he observed.

The manufacturer also highlighted products that solve real-life challenges.

On top of the list was the repairable J560 seven-way connector, designed to be replaced in a minute, without tools or cable loss. Peterson executives said it boosts sustainability by eliminating disposal of complete cable assemblies when only the connector is damaged. It also reduces parts and labor costs associated with conventional repairs.

Bladelights, the heated snowplow and auxiliary light kits were also on display. The product prevents ice and snow buildup, ensuring visibility in sub-zero conditions.

Officials also pointed out programmable strobes with turn-signal override functions for refuse and vocational trucks. Peterson also produces colored LEDs under clear lenses to satisfy image-focused tanker fleets while allowing flexible assembly on the same production lines.

All rely on the company’s in-house engineering and custom automation, which includes surface-mount circuit-board technology, molded-in terminals rather than soldered joints, and air-gap heat-management designs that eliminate potting compounds.

Marketing modernization and digital growth

Missy Pinksaw, director of marketing, said that 2025 marks a turning point in how the 80-year-old brand presents itself. A new website was launched Sept. 15 featuring market-specific navigation, LED-upgrade suggestions, and a GPS-enabled distributor locator.

The company also issued its first new catalogue set in years — two slimmer volumes, one for LED and one for incandescent products — reflecting a market that has now tipped to more than 50% LED shipments.

“We’re investing heavily in digital outreach,” Pink said. “Geofencing, retargeting, and data-driven campaigns are giving us real metrics on what works. We’re still proud of our legacy, but we want customers to see Peterson as modern and accessible.”

Workforce, culture, and automation balance

Peterson remains family-owned in its second generation, and many of its employees are second- or third-generation themselves. Executives said the company’s “person-to-person” philosophy applies not just to customers but also to employees. Anderson noted that if a customer calls during business hours, they will reach a real person, not a recording.

Like many manufacturers, Peterson faced severe hiring challenges during and immediately after the Covid-19 pandemic. Automation has since eased that strain while preserving skilled handwork in specialized lamp and harness assembly. “We see automation as a complement to people, not a replacement,” Rash said. “It lets our teams focus on precision rather than repetition.”

As it marks its 80th anniversary, Peterson’s leaders say the company’s success lies in balancing tradition with technology — a philosophy that connects its first tire pump in 1945 to its newest heated LED light assemblies today.

Anderson said that whether it’s a snowplow light or a smart-trailer harness, the goal is to build the best product possible, keep it affordable, and stand behind it.