Heavy equipment logistics is more than moving machinery from one point to another. It’s imperative for the success of large projects in many industries, including construction, energy, and manufacturing. Transport delays can lead to setbacks that jeopardize project timelines, drive up costs, and disrupt operational continuity, sometimes placing millions of dollars and valuable reputations at risk.

Failures in coordination, including missing permit deadlines and overlooking route restrictions or communication issues, can expose organizations to penalties, project overruns, and even client loss. Data-driven route planning and integrating multimodal transport minimize the risk of late and out-of-budget deliveries.

The True Complexity of Heavy Equipment Logistics

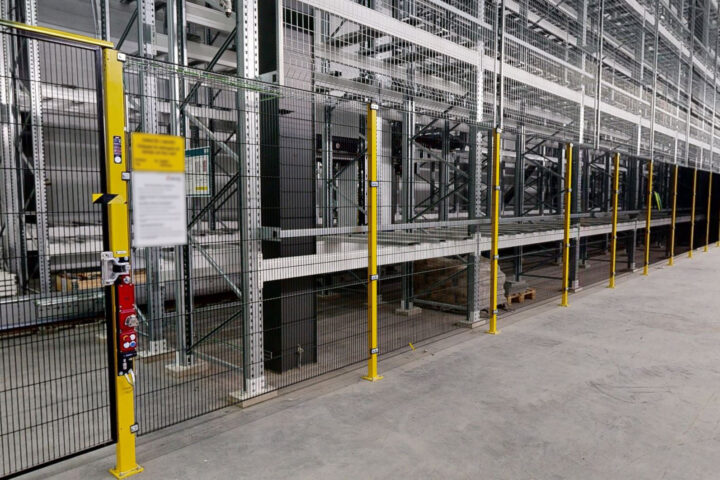

The logistics of transporting heavy equipment demand expertise with vast machinery weights that could exceed hundreds of tons. Large vehicles often have unusual dimensions and specific project constraints.

From oversized turbines and massive excavators to delicate modular process systems, each move involves meticulous planning, structural assessment, client expectations, and regulatory scrutiny to ensure everyone on the road remains safe.

Businesses often require streamlined schedules and transparent tracking, along with minimized delivery risks to keep themselves competitive. Attempting to move large or sensitive assets using a generalized freight approach often leads to dangerous loading errors, infrastructure damage, or costly interruptions that derail projects.

Specialized equipment hauling services often offer custom solutions, including specialized trailers, route engineering, permitting expertise, and end-to-end risk management tailored to specific industries.

Advanced Route Planning: Mitigating Delays and Liabilities

You can significantly mitigate delay and liability in heavy equipment logistics with advanced route planning. It blends industry knowledge with data-driven strategies. Obstacle mapping thoroughly analyzes every part of a route for physical constraints like bridge heights, road grades, weight limits, construction zones, and local regulations, increasing the likelihood of on-time and on-budget deliveries.

Risk modeling, where planners assess the likelihood and impact of disruptions, including severe weather, traffic congestion, and regulatory checkpoints, is the next step. Planners run simulations to forecast costs, time, and safety exposures.

The use of technology such as dynamic GPS systems, integrated with fleet management software, delivers real-time updates on road conditions and allows for immediate rerouting to avoid congestion or closures.

Live data feeds allow companies to plan for multistop shipments, anticipate regulatory requirements, and optimize travel time down to the minute.

Finally, digital workflow platforms allow automating documentation, dispatch, and compliance tracking.

These intelligent systems improve reliability and can cut project costs, prevent excess fuel consumption, and drastically reduce the risk of compliance penalties and accidents.

Contingency planning, when supported by innovative traffic coordination tools, ensures that critical cargo arrives safely and on schedule, even when something unexpected happens.

Regulatory and Permitting Mastery: Ensuring Compliance and Reducing Exposure

Regulatory and permitting are critical in heavy equipment logistics, as every move must comply with a patchwork of local, state, and federal rules. Companies face requirements for overweight and oversize permits, each tailored to cargo dimensions, weight, and route specifics that range from single-trip to annual and superload permits that might demand engineering studies or law enforcement escorts.

Different jurisdictions often require unique documentation, insurance, and timing requirements, which increases the importance of obtaining all approvals and permits prior to mobilizing assets.

Successful logistics operations combine compliance expertise with legal, operational, and field teams, ensuring all stakeholders coordinate on permit applications, route planning, and regulatory updates. They also use practical strategies and checklists to avoid issues that could delay a move.

The risks of non-compliance are steep, ranging from hefty fines and project shutdowns to increased insurance costs and reputational damage that can harm future business prospects. Integrated permit management speeds deployment and is vital for safeguarding operational continuity and upholding client trust.

Multimodal Integration: Optimizing for Scale and Cost

Multimodal integration is essential for heavy equipment logistics, as no single mode of transport can efficiently satisfy all project requirements. By combining road, rail, and marine assets, businesses can reach locations with infrastructure barriers and navigate regulatory or physical bottlenecks.

This flexibility allows organizations to optimize for speed and cost, using each mode’s unique advantages, which include:

- Trucks for flexible pick-up and delivery

- Rail for long-distance bulk moves

- Barges for oversize equipment

For example, shipping a massive generator might involve land transport using a specialized flatbed, and then transfer to a barge to bypass congested highways or bridge limits.

These strategies lower transportation spend and minimize project delays, in addition to lightening the load on road infrastructure and supporting operational performance.

Heavy equipment logistics drives the success of high-stakes projects, where businesses must carefully coordinate each move to meet demanding schedules, budgets, and compliance. The constant stream of data and communication enables companies to respond rapidly to unexpected hurdles, maintain safety, and proactively manage complex multimodal transfers.