Zahi Mitri knew there had to be a better way.

The vice president of innovation and technology at Challenger Motor Freight was frustrated that the company was still planning loads the old-fashioned way. Individual load planners having visibility only into the trucks assigned to them, were manually assigning loads and missing opportunities to optimize the network.

Pre-COVID-19, Mitri began researching machine learning-powered load planning solutions and even considered developing one in-house at Challenger. COVID-19 temporarily derailed those plans but when it once again became a priority, Mitri found that Optimal Dynamics had made significant progress in fine-tuning and scaling up its own offering.

Today, Challenger is in the process of rolling out Optimal Dynamics’ load planning platform and giving the company its entry into the Canadian market

“I’m embarrassed to say that we, while we were nearing a half-billion dollars in revenue, we were planning manually,” Mitri said in an interview with trucknews.com. “God bless those planners and the math they had to do to try and figure out those 50 trucks this afternoon and those 80 orders and who gets what today. That’s really the crux of the problem that we were trying to solve.”

Load planners were so focused on the trucks within their control that they weren’t seeing opportunities to take advantage of the company’s scale.

“Today, a day in the life of a truck load planner, they may manage a region. They come in and they have that set of trucks but they’re not able to necessarily see the whole network,” Mitri explained.

“So, every day we sub-optimally plan that region and it isn’t because anybody isn’t trying to do it perfectly, but it’s a manual plan. They’re using Excel spreadsheets and they’re using some cool calculators, but they’re calculators. This is really taking that calculation that we’ve done with these Excel spreadsheets and helping them to do it faster. It’s doing millions more calculations than what they can do manually and making sure they’re making the best decision. It actually optimizes the network as a whole.”

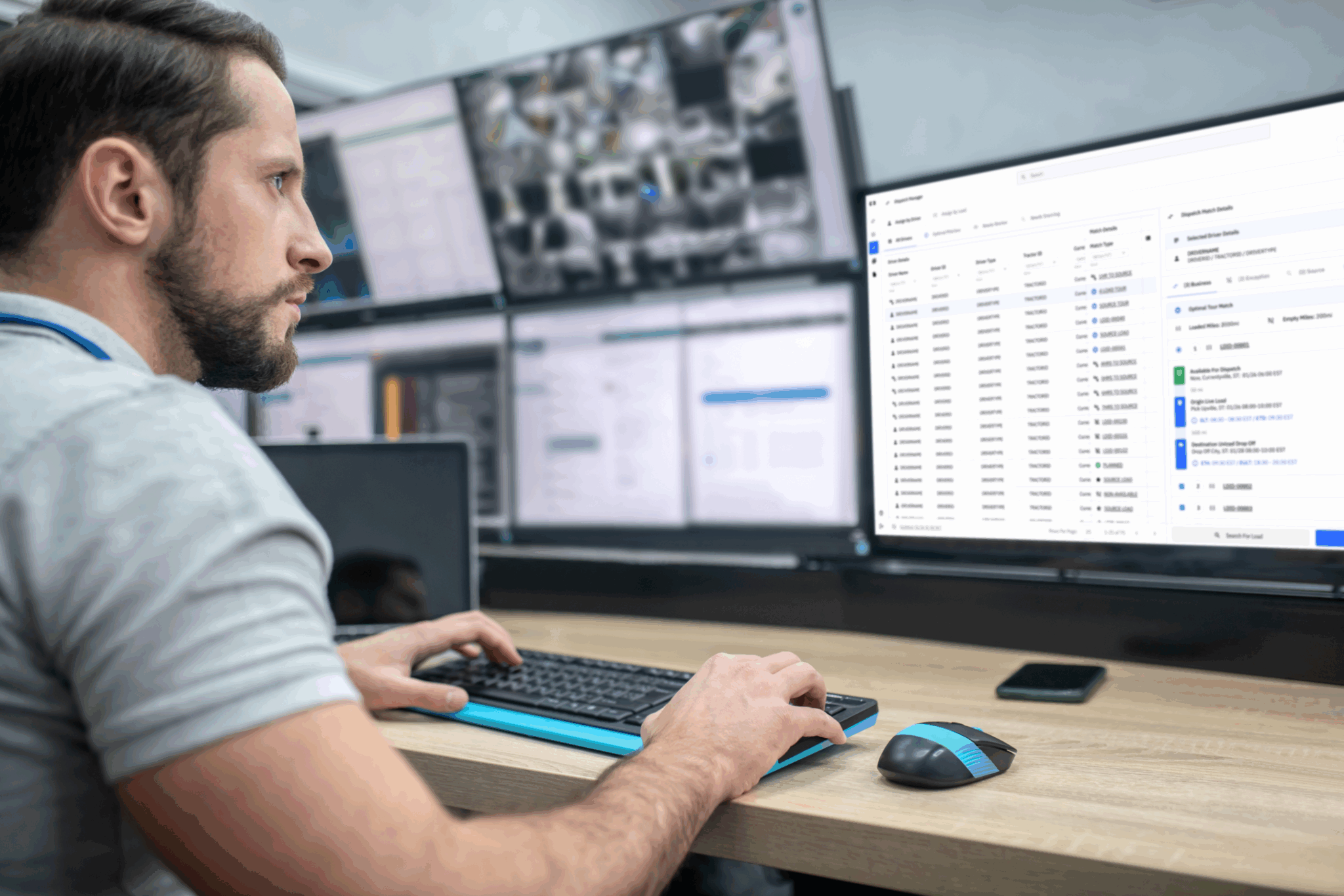

Optimal Dynamics uses machine learning to assist with that planning. It’s not a transportation management system, but integrates with them, such as TMW Suite, which is used at Challenger. It also pulls data from the fleet’s electronic logging device (ELD).

Daniel Powell, CEO of Optimal Dynamics, describes the system as “a full decision automation solution, versus a decision support solution.”

He explained “The TMS and the ELD are the key data sources, and we can also integrate into additional data feeds. If carriers have things like dwell times at certain locations, we can import that as well.”

Challenger’s Mitri said the system “breaks down these artificial borders that we’ve created for ourselves.”

He feels there will be a tangible benefit for drivers, whose time will be better utilized using the system. Empty miles will be reduced, and the company will make better use of its available capacity – even within its brokerage.

“This is the big kicker – taking our logistics arm and mixing that into the data,” Mitri said. Currently, the carrier shuns one-off transactional loads but Optimal Dynamics will help it identify when such freight actually fits with the company’s available capacity.

Mitri expects the technology will free up time for load planners to focus on other tasks while optimizing revenue per truck each week.

However, automating functions that have traditionally been manually planned requires buy-in from staff, Mitri admitted.

“I’m the biggest culprit, if you will, of change to people’s days,” he acknowledged. “So people either love me or hate me and it’s because I’m the catalyst of change. This is, right now, seen with a bit of uncertainty.”

The message to affected load planners is that they will spend more time managing exceptions versus the routine. “It’s going to allow you to do higher-order work that’s more stimulating,” he tells them.

One anticipated benefit of automating load planning is that it will stamp out bias and favoritism inherent in human dispatch decision making.

“The cool thing about Optimal Dynamics is, now it’s making those biases stick out like a sore thumb,” he said. “I think drivers are going to respect that objectivity of the tool.”

Once the platform is rolled out, Challenger plans to also use it a sales tool as it should improve the efficiency with which the company can serve its customers.

And a tool called OD Source allows the fleet to integrate into load boards, the types of one-off freight the company traditionally avoided.

“Now we can open those up and said ‘We’ll play on those load board transactionally, where it fits out network,” Mitri said. “It will only suggest it where there’s a gap you can actually fill.”