83% of auto industry logistics executives describe their organisations as resilient. However, new data from DP World shows that disruptions could cost the sector over $13 billion annually – close to 5% of an automotive logistics market valued at $295 billion.

The most cited causes of disruption are geopolitical instability and trade volatility with 91% of supply chain leaders interviewed highlighting these factors. Other threats include port congestion and detours from established shipping lanes.

The report lands at a time of intensified change for automakers and suppliers, driven by electrification and software-defined vehicles. Global shocks such as geopolitical tensions, tariffs, extreme weather and cyber attacks are adding further strain. These pressures continue to expose the fragility of just-in-time production models, where even minor delays can lead to stalled lines, missed deliveries and commercial damage. In this landscape, the confidence gap between performance and reality is a strategic risk.

This risk is already visible across the industry. In disrupted years, 60% of automotive companies lose more than a month of operations. Four in five report more customer complaints, 72% have lost business or contracts, and 63% say their brand reputation has suffered. Supply chain failures are no longer only operational issues. They also impact customer trust, contract value and long-term brand strength.

As a result, logistics are increasingly on the boardroom agenda: 91% of auto supply chain leaders say disruptions have been escalated to senior executives, signalling a growing strategic importance at the top level of organisations.

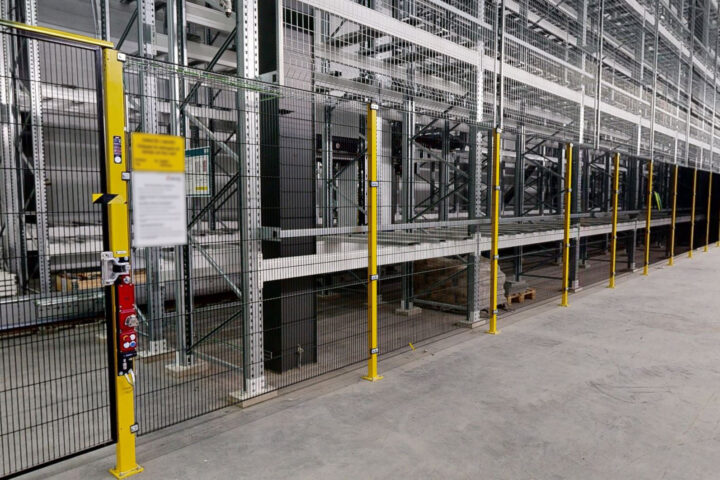

DP World’s research also highlights how integrated logistics investment can strengthen resilience. Companies that take a coordinated approach, investing in areas such as warehousing, international freight, last-mile delivery, compliance, production logistics, and sustainability, report around 20% lower disruption costs and recover up to 60% faster than those with limited investment focus. The most significant performance gains come from risk management and resilience planning, which directly help manufacturers anticipate, absorb, and recover from shocks. For lean, time-sensitive supply chains, this difference can protect margins, preserve customer relationships, and strengthen competitiveness over time.

As the industry navigates the transition through electrification and software-defined vehicles amid continued threats of disruption, closing the confidence gap will be critical to sustaining growth.

Beat Simon, Global Chief Operating Officer, Logistics, DP World, said: “Our research reveals a clear confidence gap. Many automotive companies believe they are resilient, but our data shows a strategic blind spot costing $13 billion a year. As an end-to-end supply chain partner to the global auto industry, we believe these insights are critical for OEMs and their ecosystems. In just-in-time environments, even small delays can lead to broader commercial and brand risks. This is where a focus on resilience becomes essential, and our findings show a strong link between resilient supply chains and commercial performance.”

David D’Annunzio, Global Vice President and Automotive Vertical Lead, DP World, said: “ We understand the pressure our OEM customers face to deliver in a constantly changing environment. Every delay has a ripple effect on production schedules, partners and customers. That’s why we’re investing in solutions that help manufacturers build resilience, recover faster and maintain reliability, even in the most complex supply chains.”

These findings are drawn from a wider global study of 680 senior logistics leaders across eight industry verticals, including 75 senior supply chain decision makers within automotive businesses. It includes primary surveys and a data model which connects disruption costs with logistics investment, company size and reputational impact – providing a robust and executive-level view of supply chain resilience and the cost of disruption.