AutoStore, a leader in automated order fulfilment technologies, has introduced its Fall 2025 product range, designed to address major warehouse and logistics challenges including labour shortages, increasing throughput demands and multi-temperature handling.

Key additions in the portfolio

Among the seven new or enhanced features, the most significant are:

- AutoCase: Enables full-case loading and unloading as part of the same system that handles piece-picking. AutoStore says the innovation allows operators to “combine case handling and piece-picking in one flow”, merging two traditionally separate operations into a single high-density system.

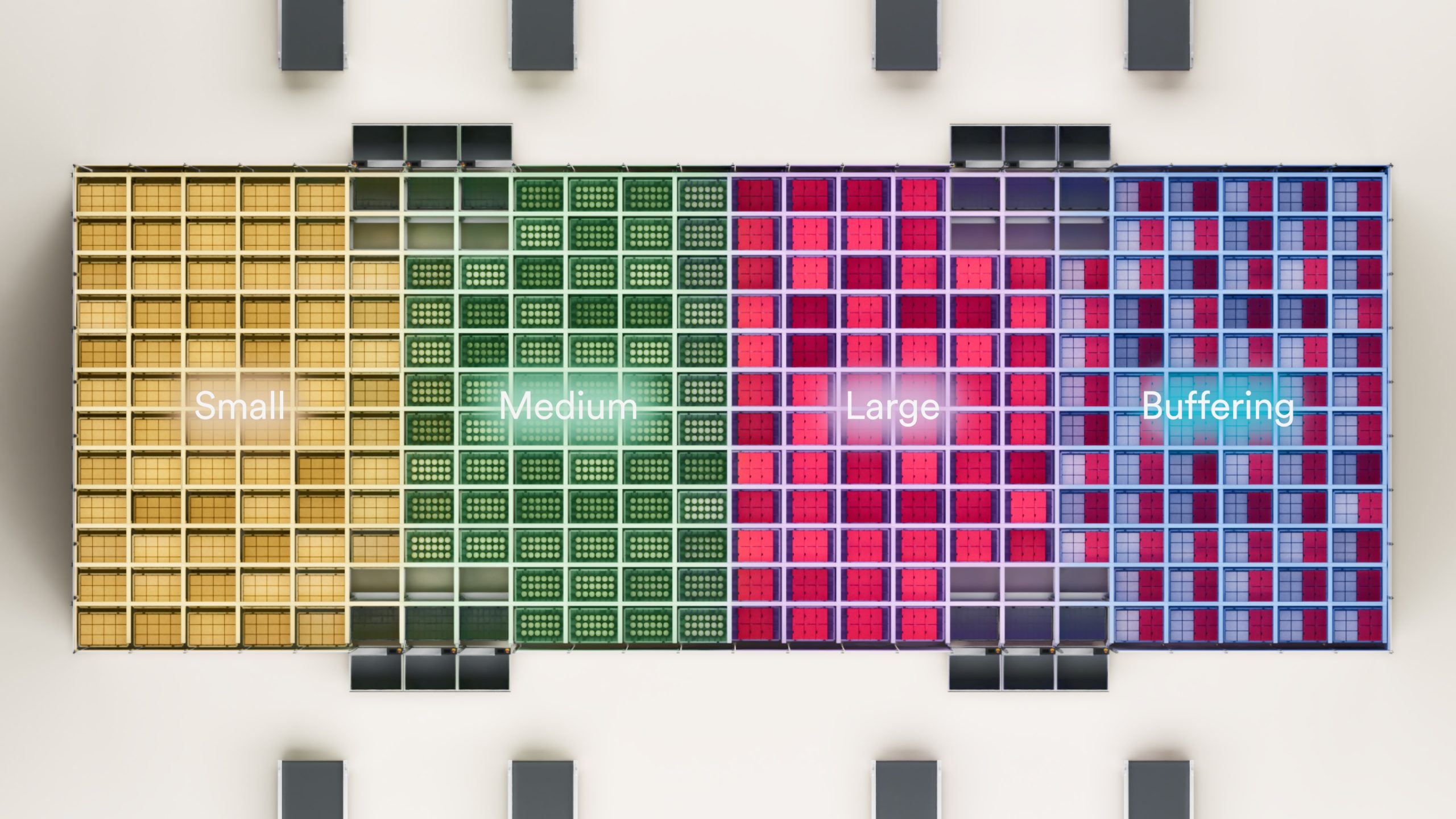

- FlexBins: Allows different bin sizes within the same Grid structure, enabling a greater SKU assortment and higher storage density without sacrificing speed.

- Frozen-Only Grid: A variant of AutoStore’s multi-temperature solution configured specifically for frozen goods, reducing energy use and enhancing worker safety in cold-chain operations.

- Other enhancements include: Improvements to CarouselAI (faster retrieval, outbound routing, lighter item support), fire-sprinkler system redesign (reducing installation cost by up to 35 %), floor-flatness laser scanning (reducing floor-preparation time) and “CubeDeploy” software installation improvements for faster updates with minimal downtime.

Why it matters for the logistics sector

Warehouses and fulfilment operations are under pressure from three converging trends: more SKUs, faster delivery expectations and increasing automation demands amid labour constraints and rising costs. AutoStore states these new features are designed to “turn bottlenecks into opportunities for higher performance” by enabling operations to “store and move things for everyone, everywhere”.

With full-case handling now integrated alongside piece-picking in one system (via AutoCase), operators can eliminate separate systems or manual workarounds for cases—cutting complexity and improving throughput. FlexBins’ ability to accommodate different bin sizes in one grid responds to the need for operations to carry wider assortments under one roof. And the Frozen-Only Grid addresses the growing e-grocery and pharma cold-chain segment where automation solutions remain scarce.

Industry reaction & pilot customers

Early adopters are already in place. For instance, Veloq (an AI-powered grocery automation firm) is piloting FlexBins and reports that storing a wider range of products in the same Grid is “critical for a fast-growing grocery business.”

AutoStore’s Chief Product Officer, Parth Joshi, commented:

“At AutoStore, everything starts with the customer. These seven launches address major warehouse challenges, strengthen our portfolio and expand capabilities to maximise ROI…”

Market context & growth roadmap

Founded in Norway, AutoStore says it now has more than 1,700 systems deployed in nearly 60 countries. The Fall 2025 portfolio launch follows earlier milestones including the debut of CarouselAI and the VersaPort workstation solution, expanding into smaller business automation with the Pio product line and even a robotic vertical farm project in partnership with OnePointOne.

For logistics operators, the new features may offer a way to future-proof warehousing infrastructure by combining flexibility (multi-bin sizes), speed (case + piece flows) and thermal zone capability (frozen storage) in a unified automation ecosystem.

Outlook for logistics business

The logistics sector is facing continued pressure to deliver faster, cheaper and with fewer resources. As warehouses evolve into high-density, multi-temperature, multi-SKU operations, automation providers like AutoStore are racing to add capabilities beyond simple pick-and-pack. The Fall 2025 launch signals AutoStore’s ambition to move into full case flow, mixed-size handling and cold-chain – three key growth areas in the sector.

Operators evaluating automation projects in the next 12 – 24 months should watch for:

- The total cost of ownership and installation timeline reductions (AutoStore claims cut-downs in sprinkler and floor prep costs).

- The flexibility of bin sizing and temperature zones — critical in grocery, healthcare and omni-channel fulfilment.

- The integration of case handling with piece picking, which may reduce system hand-offs and complexity.