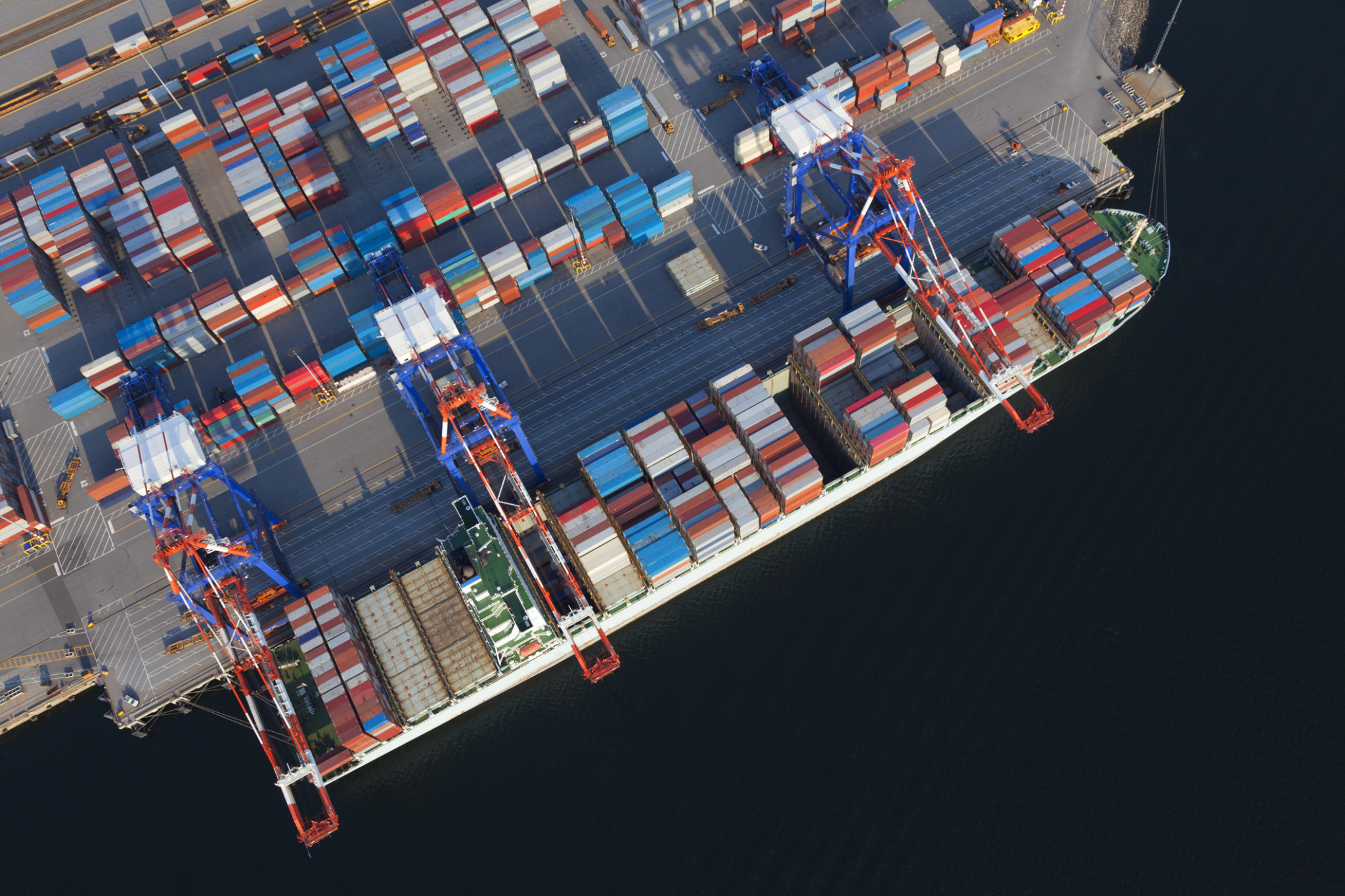

Teamsters Canada is speaking out against autonomous truck testing at the Port of Prince Rupert in B.C., saying the technology threatens unionized jobs and ignores simpler, proven solutions to boost capacity. The port, meanwhile, says the test is one of the ways to prepare for a sharp rise in drayage demand as two major logistics projects come online by 2030.

The expansion projects that are underway — CANXPORT and the South Kaien Import Logistics Park (SKILP) — will require a seven-fold increase in drayage capacity by 2030, says Olivia Mowatt, senior communications officer at the port.

“Currently, about 150 drayage moves are performed each day at the Port of Prince Rupert. By 2030, with both CANXPORT and SKILP in operation, our port will need to be able to handle an estimated 1,100 moves per day,” she wrote in an email to trucknews.com. “There are concerns of potential drayage driver shortages in the future, like situations faced during the Port of Prince Rupert’s record volume years in 2019 and 2020.”

The CANXPORT facility, operated by Ray-Mont Logistics, will add 400,000 TEUs of annual transloading capacity for Canadian exports such as agriculture, forestry, and plastic resin products.

SKILP, a joint venture with the Metlakatla Development Corporation, will offer a 100-door cross-dock facility to support growing import logistics needs.

Both projects will depend on increased truck moves between Fairview Terminal and the new sites.

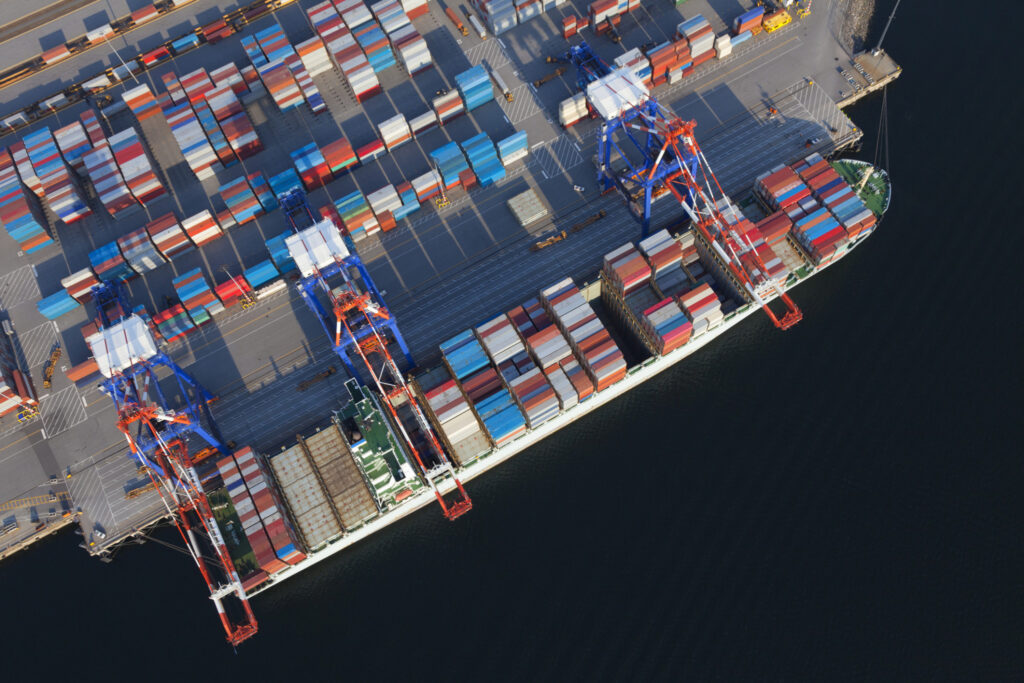

The port authority claims ‘many options are being explored as potential solutions to augment the labor force’, including a pilot project to test autonomous drayage trucks through a partnership with Innovate BC, Gat Leedm Logistics, and NuPort Robotics.

However, Christopher Monette, director of public affairs for Teamsters Canada, a union representing 36 drivers and maintenance workers at the port, argues that the port has not exhausted other more practical options, saying there are ‘cheaper, better, easier ways to improve productivity that don’t threaten the jobs of hard-working Canadians.’

While Monette acknowledged there is an issue with attracting workers to Prince Rupert, but did not fully accept the claimed driver shortage.

“We’ve been able to scale up to 70 or 80 drivers in the past,” he told trucknews.com, when asked about the current pool of around 60 drivers at the port. Speaking of the increased capacity for drayage moves, he advocated for alternative methods such as using B-trains or bomb carts on the port’s private roads to increase hauling capacity. “We do believe we could double and even quadruple the current capacity of our trucking operations there.”

Monette said the union is not opposed to innovation but questions the rationale behind investing in what he believes is unproven technology instead of listening to drivers and scaling up established tools. “There seems to be this pursuit of the latest gadgets, and confusing that pursuit with proper management,” he said. “In reality, it’s mismanagement disguised as innovation… we seem to be listening to tech bros and the consulting class and chasing after the latest gadgets. Again, very frustrating for our members.”

The autonomous truck testing is now in its second stage, as the first round took place last summer, and a safety driver was present behind the wheel at all times.

Though no Teamsters members participated in the trial directly, Monette believes it was too limited in scope to demonstrate the technology’s real-world value. He says the union has learned that the truck was not able to map out the entire facility and was ‘only going to the grain terminal and back to the port gate’. He suggested that while the truck was carrying a weighted load, it was not transporting actual cargo. “It remains to be seen to what extent any of this could actually be helpful,” Monette said. When asked by trucknews.com to confirm or deny the details of the first test, the Prince Rupert Port Authority did not respond directly.

He also raised concerns over the safety of the last testing phase, saying that union drivers faced uncertainty and confusion when encountering the automated truck on the same roadway.

Monette added that automation is not a silver bullet for labor issues. “There’s no such thing as a fully automated port facility. There’s always going to be human labor involved, and as you increase with degrees of automation, there’s even more specialized labor that is involved,” he said.

Mowatt, however, says the goal of autonomous truck testing is to complete proof-of-concept work focused solely on future drayage services, not terminal operations, with a driver always behind the wheel.

“There are no plans to introduce autonomous technology in terminal operations. The only purpose is to test its potential use for drayage trucking services in the future,” she wrote. “Autonomous trucks are only being considered to handle the incremental volumes beyond what the current drayage driver pool is able to move.”

In parallel, the port says it is also participating in the Heavy Duty Zero-Emissions Vehicle (HDZEV) project to evaluate heavy-duty low- and zero-emissions trucks.